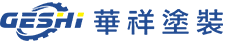

Selecting the right

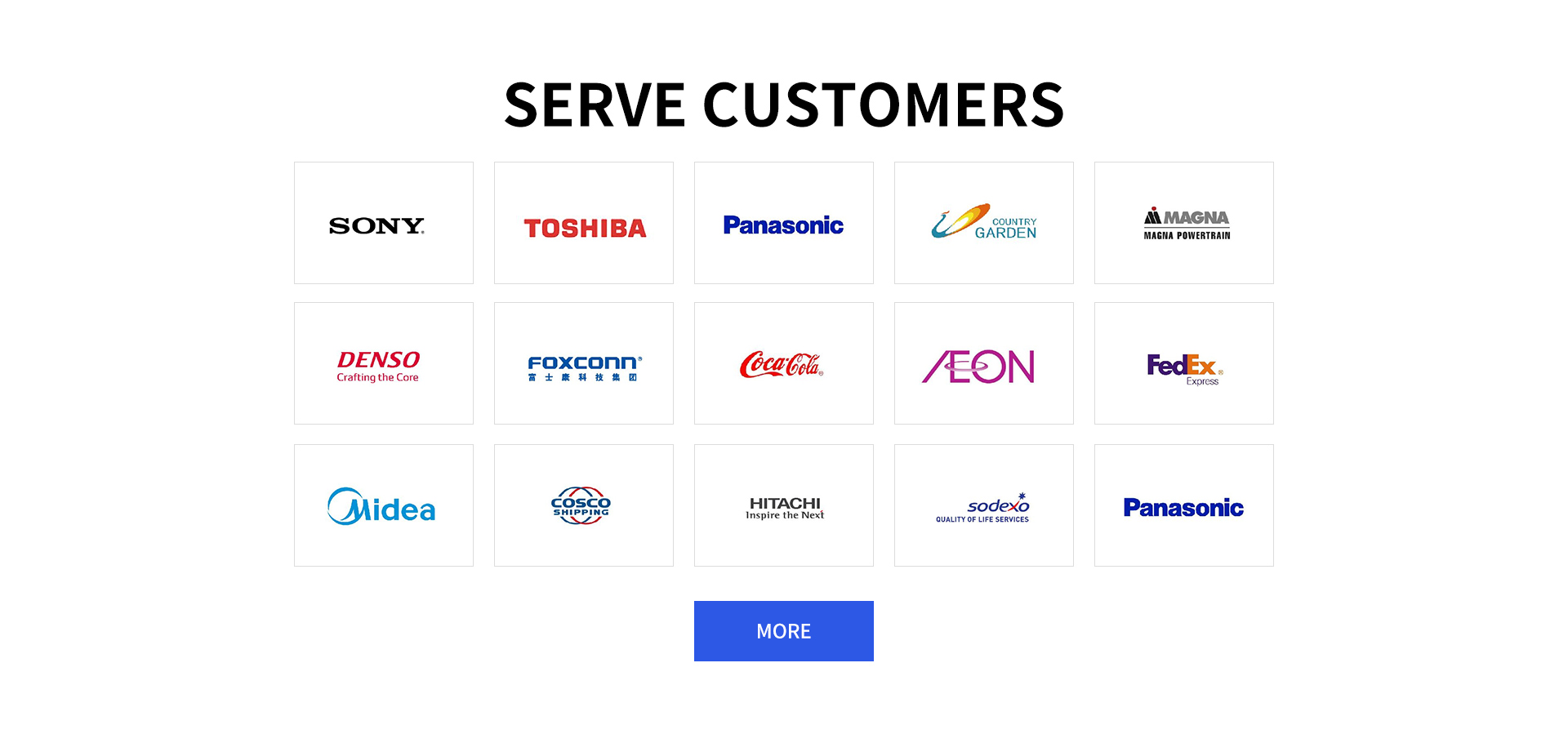

powder coating oven supplier is crucial for obtaining high - quality powder - curing equipment. Suppliers generally offer two main types of products:

Small - scale suppliers typically provide table - top powder coating ovens, with prices starting at approximately $500. These ovens are well - suited for hobbyists and small - scale DIY workshops. They are compact, easy to operate, and equipped with basic temperature - control functions.

Large - scale industrial suppliers offer conveyor - type powder coating ovens, starting at $10000. These ovens come with advanced temperature - control systems, high - power heating elements, and large - capacity chambers, making them ideal for continuous mass production.

These ovens function by heating the coated workpieces to a specific temperature, which fuses the powder into a smooth and durable finish. They are constructed using high - quality insulating materials to ensure energy efficiency. Additionally, suppliers often provide installation services, training on operation and maintenance, and after - sales support.

In the jewelry - making industry, small - scale ovens are used to cure powder - coated jewelry. In automotive parts manufacturing, large - scale industrial ovens are employed to cure the powder coatings on engine components. In metal furniture production, the choice between the two types of ovens depends on the production scale.

Q: How can I set the correct temperature in the powder coating oven?

A: First, refer to the powder manufacturer's instructions to determine the recommended curing temperature. Then, use the oven's temperature - control panel to set the desired temperature.

Q: What should I do if the powder coating has bubbles after curing?

A: Bubbles may be caused by over - heating or trapped air. Try slightly reducing the curing temperature or pre - heating the workpiece to eliminate moisture.

Q: Can I customize the size of the powder coating oven?

A: Many large - scale suppliers offer customization services. It is advisable to discuss your specific requirements with them in advance.

Q: How often should I clean the powder coating oven?

A: Clean the oven after every 5 - 10 uses. Remove any powder residue and check for signs of wear and tear.

Q: How do I select the appropriate powder coating oven supplier?

A: Consider factors such as your production volume, budget, and the level of technical support you require. For small - scale projects, a small - scale supplier is usually sufficient. For large - scale industrial production, a large - scale industrial supplier is more appropriate.

Title:Choose the Ideal Powder Coating Oven Supplier

Link:http://www.hpowdercoating.com/coen/show/642.html

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com