1. Small Powder Coating Spray Booth Overview and Components

Small Powder Coating Spray Booths are compact, enclosed systems designed for controlled powder application. Key components include a spray chamber, exhaust fan, powder collection tray, lighting, and optional filtration systems. Built from durable steel or aluminum, these booths ensure a clean workspace and efficient powder adhesion for small-scale projects.

2. Applications of Small Powder Coating Spray Booths

These booths are ideal for automotive repair shops, furniture refinishing, metal crafts, and small machinery coating. They provide a contamination-free environment, reduce overspray, and improve workplace safety for hobbyists, DIY enthusiasts, and small businesses.

3. Small Powder Coating Spray Booth Pricing

Prices range from 1,000forbasicmodels∗∗to∗∗10,000+ for advanced units with HEPA filters and powder recovery systems. Mid-range options (3,000–6,000) suit most small operations, offering features like adjustable airflow and energy-efficient lighting.

4. Proper Use of Small Powder Coating Spray Booths

Ground the booth and workpiece to prevent static discharge.

Adjust the exhaust fan speed to control airflow and minimize overspray.

Maintain a 6–12 inch spray distance for even coverage.

Activate the powder recovery system to recycle excess powder.

Clean the booth interior and filters weekly to ensure optimal performance.

5. How to Choose a Small Powder Coating Spray Booth

Booth Size: Select based on the largest workpiece and available workspace.

Powder Recovery: Opt for models with efficient recovery systems to reduce waste.

Safety Features: Look for grounded cables, fire suppression systems, and proper ventilation.

Energy Efficiency: Prioritize booths with LED lighting and variable-speed fans.

6. Safety Precautions for Small Powder Coating Spray Booths

Wear respirators, gloves, and goggles to protect against fine particles.

Ensure proper grounding to eliminate fire risks from static sparks.

Install fire extinguishers nearby and avoid flammable materials in the workspace.

Regularly inspect electrical components and exhaust systems.

7. Design Advantages of Small Powder Coating Spray Booths

Modern designs focus on efficiency and user convenience. Features like quick-access panels, removable powder trays, and energy-efficient lighting simplify maintenance. Compact sizes save space, while modular setups allow future upgrades.

8. Small Powder Coating Spray Booth Q&A

Q1: Can small powder coating spray booths handle automotive parts?

A: Yes, they are suitable for small parts like wheels, brackets, or motorcycle components.

Q2: Do I need a filtration system in a small booth?

A: Filtration systems improve air quality and powder recovery, but basic models can operate without them.

Q3: How often should I clean the booth filters?

A: Clean filters weekly and replace them every 3–6 months, depending on usage.

Q4: Are small powder coating spray booths eco-friendly?

A: Yes, they minimize overspray and allow powder recycling, reducing waste.

Q5: What’s the key to maintaining booth efficiency?

A: Regularly clean the interior, inspect airflow systems, and replace worn components.

This guide provides essential insights into small powder coating spray booths, helping users achieve professional results while ensuring safety and efficiency in small-scale operations.

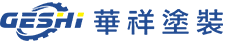

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com